Vacuum insulated cryogenic tube

Air separation grade:

Product specification (oxygen/nitrogen/argon):

Time:

Classify

keyword

Vacuum insulated cryogenic tube

Product details

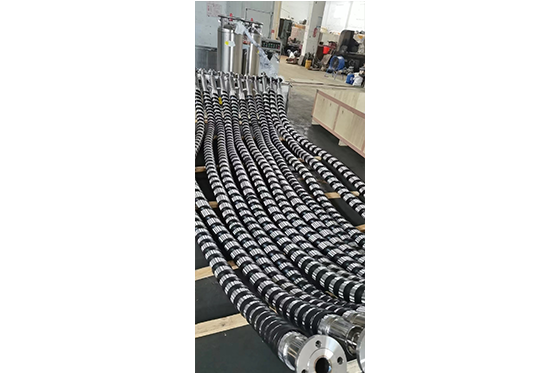

The vacuum insulated cryogenic tube is made of double-layer stainless steel metal tube, and the interlayer is added with multi-layer thermal insulation composite material to maintain a high vacuum state. Therefore, the cold insulation effect is good, and the hose surface is free of water and frost during use. The bending radius is small, easy to use, and the length can be determined according to user requirements.

1、 Introduction of Vacuum Insulated Cryogenic Pipe

It is mainly used to transport various cryogenic liquefied gases such as liquid oxygen, liquid nitrogen, liquid argon, etc. between air separation equipment or cryogenic liquid storage equipment with long distance and large flow.

The advantages are: no loss, long application time, etc.

2、 Main technical indexes and characteristics of vacuum insulated cryogenic tube

1. Heat insulation form: high vacuum multi-layer multi-screen heat insulation;

2. Applicable media: liquid oxygen, liquid nitrogen, liquid argon, liquid helium, liquid hydrogen, liquefied natural gas

3. Design temperature: - 269 -+80 ℃;

4. Working temperature: - 200 ℃ -+80 ℃;

5. Average cold loss of pipeline: ≤ 0.5W/M;

6. Vacuum leakage rate of pipeline: ≤ 1 × 10-10Pa·m3/s;

7. Pipe material: inner pipe S30408/S31603 fluid stainless steel pipe

8. Corrugated pipe S30408/S31603 corrugated stainless steel pipe

9. Outer pipe S30408/S31603 stainless steel polished pipe.

3、 Main features

1. Reasonable design structure, no sweating, low evaporation rate. Based on the introduction of Japanese manufacturing technology of high vacuum multilayer insulation vessels, the company has optimized the structure and manufacturing process, and developed various vacuum tube shielding technologies.

2. The design adopts reasonable compensation structure, with stable performance, safety and reliability. The heat insulation support at the end of the pipeline adopts the balanced strength design, which ensures the double reliability of heat insulation and strength.

3. Adopt high-quality thermal insulation materials. In order to achieve good thermal insulation and radiation resistance of vacuum tubes, our company uses the binding layer and ultra-thin shielding materials produced at home and abroad. In order to slow down the attenuation of vacuum in the vacuum tube interlayer, a high-efficiency adsorption bag is set and high-quality adsorption materials are selected.

4. Beautiful appearance, segmented production, convenient installation and maintenance, and long service life. The outer pipe, elbow and outer pipe corrugated compensator are all made of polished stainless steel. Vacuum flange connection is adopted between vacuum pipes, which is convenient for installation, disassembly and maintenance.

5. The vacuum tube has less cold loss and is guaranteed. Less than 1.33 × 10-3Pa sealing vacuum; Below 1 × 10-10Pa · m3/s pipeline leakage rate.

6. The cleaning and drying of materials are strictly handled and controlled according to the oxygen medium. This product is used in food, medical, metallurgy, chemical, machinery, medical, national defense, scientific research and other industries with high requirements.

7. Ensure stable and reliable product quality. Japan's high vacuum evacuation and binding technology shall be adopted and carried out in strict accordance with relevant regulations.

8. The pipeline is equipped with high vacuum multilayer multi-screen insulation low temperature stop valve and check valve, with good overall cold insulation effect.

achievement

|

序号 |

客户名称 |

产品名称 |

主要参数 |

年份 |

| 1 |

Ningbo Hechuang Cryogenic Technology Co., Ltd |

vacuum tube |

LN | 2020 |

| 2 |

Hangzhou Chuangwei Industrial Co., Ltd |

vacuum tube |

LN\LO\LAr | 2021 |

| 3 |

Lianhua Technology (Taizhou) Co., Ltd |

vacuum tube |

LN | 2021 |

| 4 | Taiyuan Satellite Base |

vacuum tube |

LN\LO | 2021 |

| 5 |

Zhejiang Lepu Pharmaceutical Co., Ltd |

vacuum tube |

LN | 2022 |

| 6 |

711 Research Institute of China Shipbuilding Heavy Industry |

vacuum tube |

LN\LO\LAr | 2022 |

| 7 |

Quzhou Hangyang Special Gas |

vacuum tube |

LO | 2022 |

| 8 |

Lianhua Technology (Taizhou) Co., Ltd |

vacuum tube |

LO | 2022 |

|

9 |

Zhejiang Guobang Pharmaceutical Co., Ltd |

vacuum tube |

LN |

2022 |

| 10 |

Zhejiang Haixiang Chuannan Pharmaceutical Co., Ltd |

vacuum tube |

LN | 2022 |

specifications

|

Pipe specification (mm) |

Drift diameter |

DN10 | DN15 | DN20 | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 |

|

Inner tube |

12 | 18 | 25 | 32 | 38 | 45 | 57 | 76 | 89 | 108 | 133 | 159 | 219 | |

|

Outer tube |

57 | 76 | 89 | 89 | 108 | 108 | 114 | 133 | 159 | 180 | 219 | 245 | 325 | |

|

working pressure |

Designed according to user needs |

|||||||||||||

|

Design temperature |

-196℃/-269℃ |

|||||||||||||

|

Working medium |

LO2、LN2、LAr、LH2、LNG等 |

|||||||||||||

|

material quality |

S30408或S301603(customized according to users) |

|||||||||||||

|

Interlayer pressure |

≤0.004Pa |

|||||||||||||

|

structural style |

High vacuum multilayer insulation |

|||||||||||||

|

Vacuum leakage rate of pipeline |

≤1*10-10Pa*m3/S |

|||||||||||||

|

|

|

|

|

The company is formed for a technology-based entrepreneurial team. With strong technical support and 20 years of industry experience, the technical engineers originated from Germany's refrigeration technology, laying a solid foundation and guarantee for the stability, innovation and quality of the equipment! The company has a registered capital of 2 million yuan and covers an area of more than 5000 square meters. It is a high-tech enterprise integrating the production, R&D and sales of reliability equipment, environmental simulation equipment and laboratory test equipment.

Marcus Vitruvius Pollio, the imperial architect and engineer of ancient Rome, wrote the "Ten Books of Architecture", which is the only architectural monograph left over before the Middle Ages in Europe. This book later became the classic of the architecture circle in the Renaissance, Baroque and Neoclassical periods, and still has a profound impact on the architecture circle. Around the 17th century, a descendant of Vitruvius moved to the Holb region on the Neckar River in Germany.

|

Performance Parameters |

|

|

Rated Voltage |

24VDC |

|

Rated Power |

75W |

|

Rated Speed |

120rpm |

|

Unload Speed |

150rpm |

|

Unload Current |

≦0.8A |

|

Self-lock Torque |

≦0.5N.m |

|

Gear Ratio |

15:1 |

|

Protection Class |

IP44 |

|

Insulation Class |

B |

|

Motor Noise |

≦55dB |

|

Motor Weight |

2.5kg |

|

电Motor Cable |

450mm 8P |

Recommended products

Online Message