Air separation equipment

The gas air separation equipment can simultaneously produce high-purity oxygen, nitrogen, argon and other gases, and can produce a small amount of liquid products. The company has the assembly capabilities of R&D, design, manufacturing, installation and commissioning of small and medium-sized air separation equipment, and is good at providing customers with competitive air separation project design solutions. The gas air separation equipment is divided into two processes: external compression and internal compression. The external compression process is the process that oxygen is compressed to the required pressure by the oxygen compressor outside the tower, which has the characteristics of low energy consumption, low cost and flexible operation; Internal compression refers to the process that liquid oxygen is pressurized to the required pressure in the tower by liquid oxygen pump and then gasified to gaseous oxygen, which has the characteristics of strong liquid production capacity and can produce high-pressure oxygen. The company has completed the technical reserve of 3000~20000 cubic meters of standard air separation equipment.

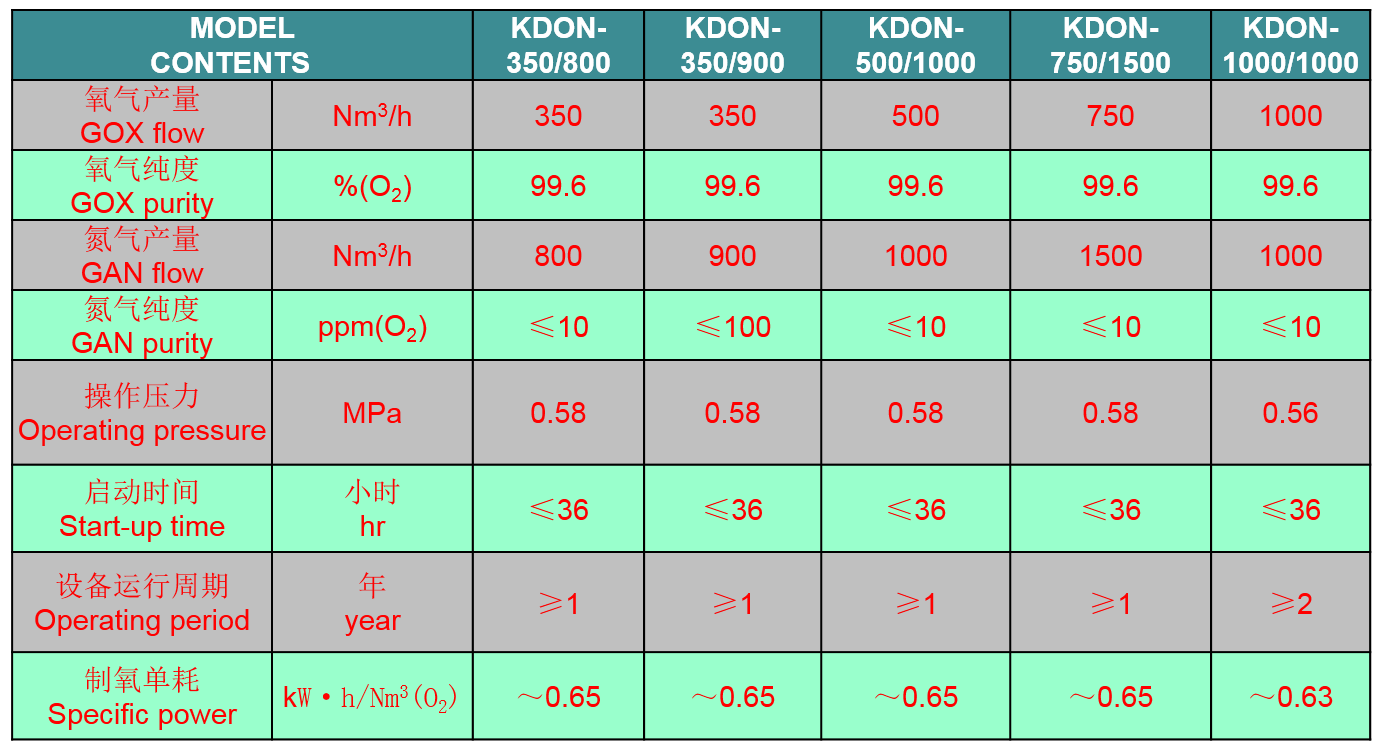

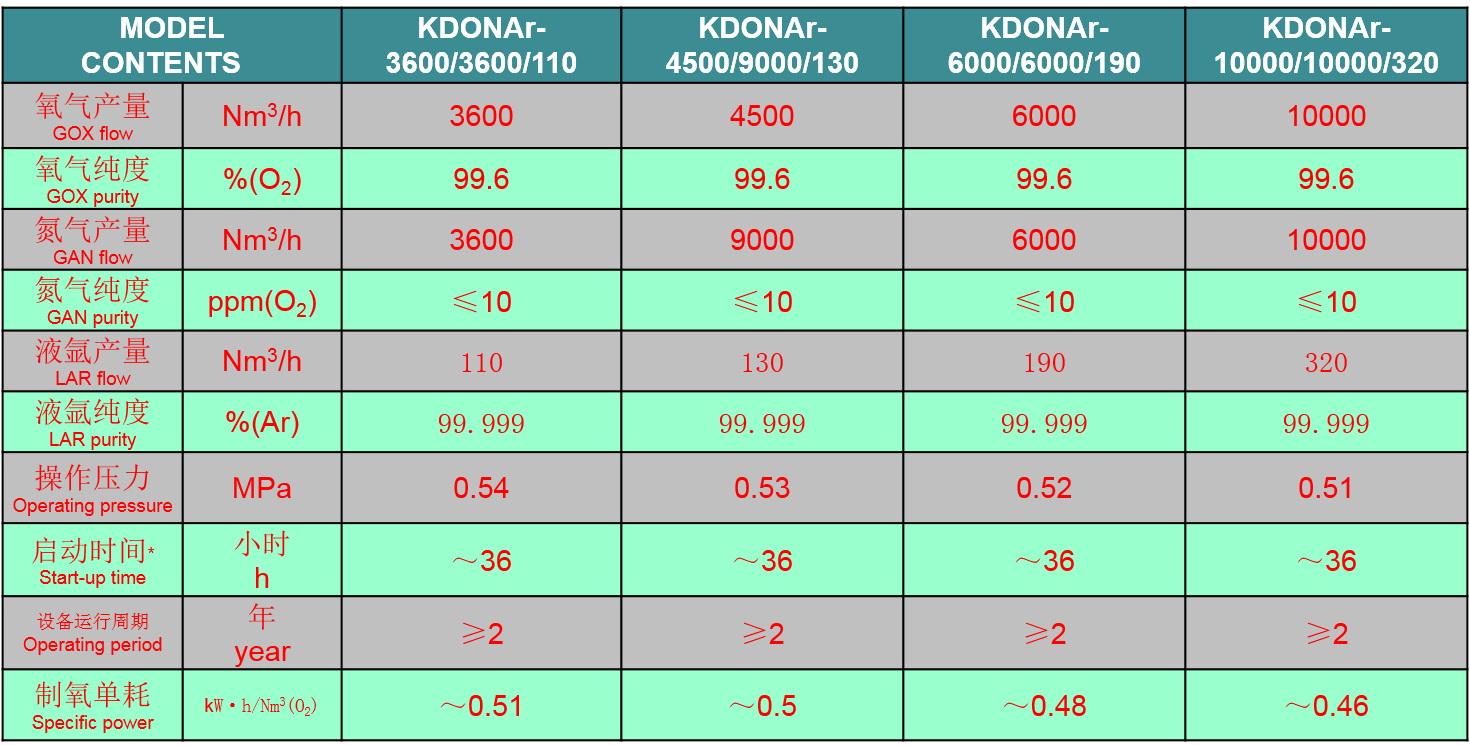

Technical indicators of standard air separation equipment

Main technical index 1 of medium and small air separation equipment series products (without argon)

Main technical index 2 of medium and small air separation equipment series products (with argon)

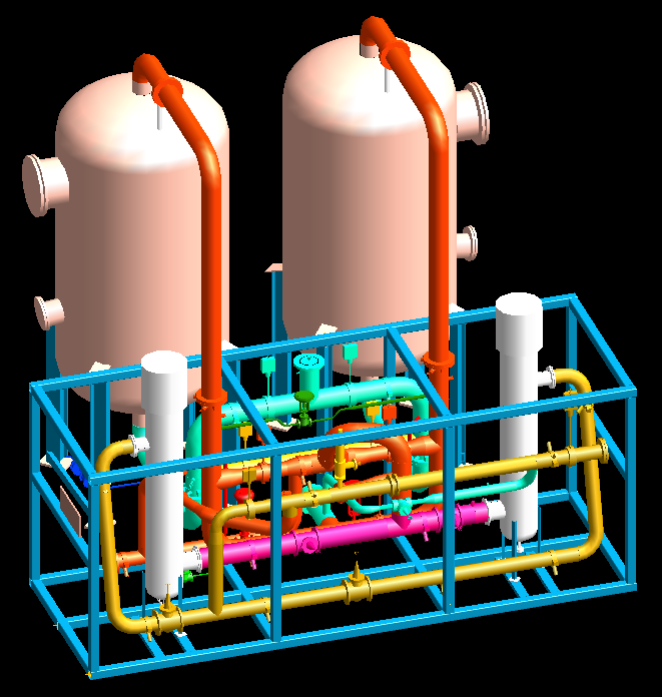

Composition structure and model

Molecular sieve purification system

|

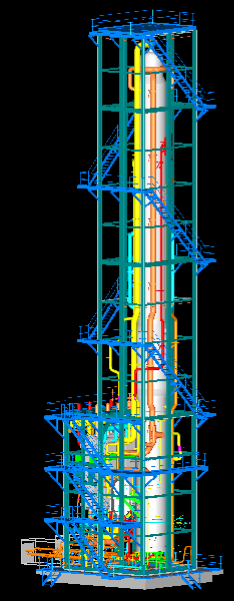

Distillation system of air separation plant - model without argon cold box |

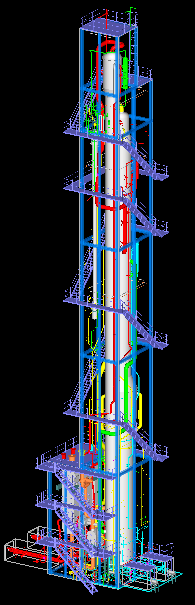

Distillation system of air separation plant -- model with argon cold box |

Air separation grade :7500

Product specification (oxygen/nitrogen/argon) :

time:2022

Air separation grade :11000

Product specification (oxygen/nitrogen/argon) :11000/10000

time:2018